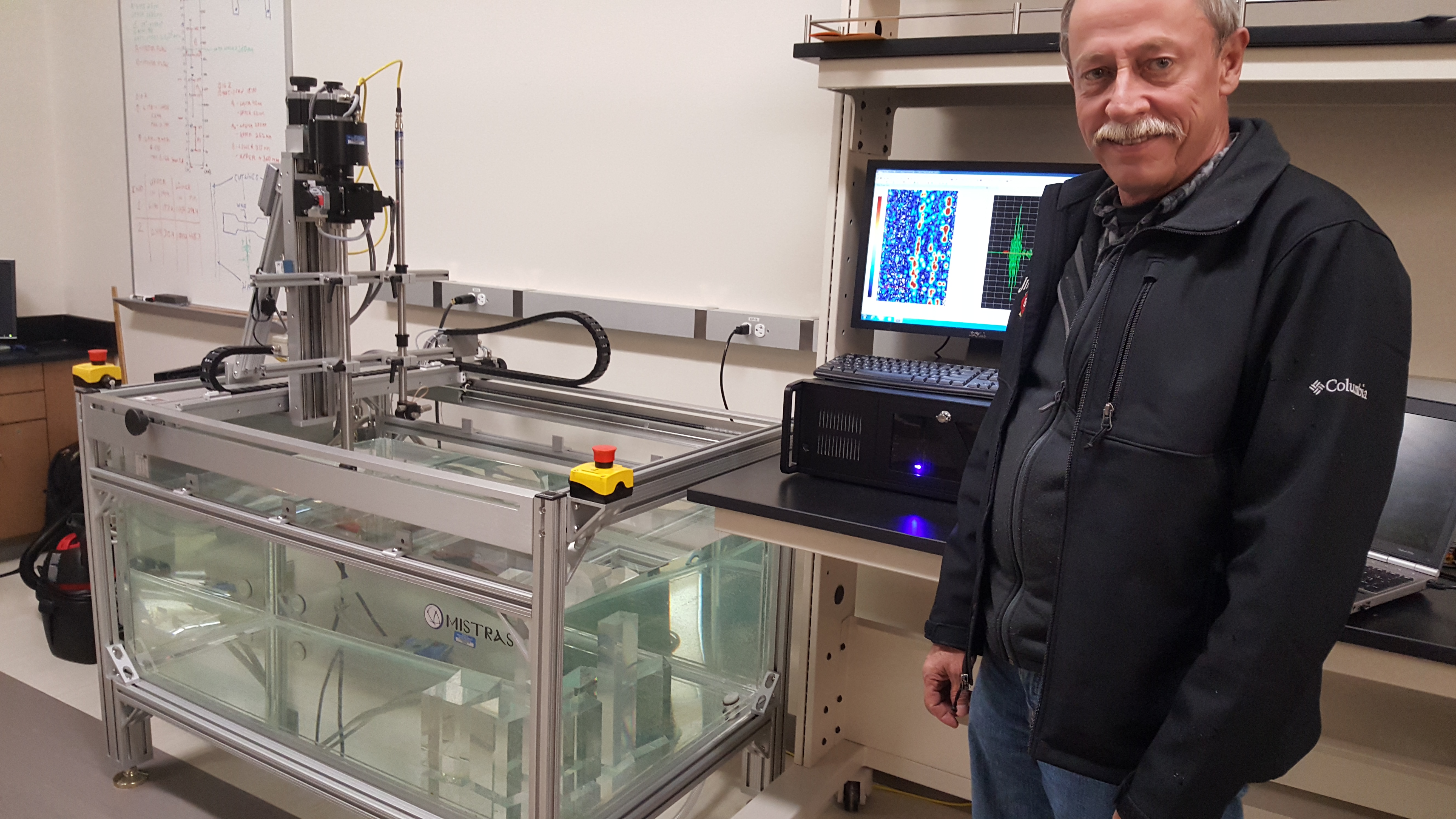

Dr. George BungetAssistant Professor, Engineering Physicsgbunget@murraystate.edu Dr. Bunget received his BS in Mechanical Engineering from Polytechnic University of Bucharest (Romania) and he completed his M.S. and PhD at NC State University specializing in Smart Materials and Adaptive Structures. He performed research on acoustic testing and developed for Michelin an impact acoustic method and computer control apparatus to detect internal defects and delaminations in truck tires (patent no. WO2015 69218 A1). He has led the research of developing an ultrasonic scanning system with guided waves to detect internal delaminations and kissing bonds in multilayer structures for inspection of Solid Rocket Motors (PI for US Air Force). He was principal investigator for US Air Force to develop an eddy current inspection system to quantify cracking damage of gun barrels (gatling gun of A-10 aircraft). He conducted research on aluminum alloy sensitization was part of a team that developed an embedded monitoring system for NAVSEA. He contributed extensively on data analysis and design of artificial neural networks in developing an embedded electrochemical impedance spectroscopy platform for in situ coating health monitoring of carbon steel tanks and inclosures within Navy submarines and ships. He has expertise in several disciplines such as NDE acoustics, ultrasonics, eddy current, and electrochemical impedance spectroscopy methods. His primary research interests have concerned nondestructive evaluation and system dynamics and control with applications in aerospace, navy, and automotive industries. In these areas, his attention focused on developing advanced acoustic, and eddy current techniques both for inspection and structural health monitoring. Currently, he works for US Army Research Laboratory to develop a Nonlinear Ultrasonic System for assessing the remaining useful life of hot section components in turboshaft jet engines powering the Black Hawk and Apache helicopters. On this project he developed a technique of extracting the amplitude of higher harmonics for nonlinear ultrasonic measurements (US Provisional Application 62/526,655 - June 29, 2017). Together with the NDEL team at Murray State, he is also working on a project of natural gas pipeline for Vectren Holdings, Evansville, IN. His focus is related to improving the resolution of detecting flaws in pipeline welds and to develop techniques of 3D flaw reconstruction. |

Stan HenleyMechanical Integrity Engineering Specialistshenley1@murraystate.edu A native of Murray, KY, Stan Henley is a retired U.S. Navy officer. While in the Navy, Mr. Henley completed the Advanced Electronics Technician and the Naval Nuclear Power School curricula. He focused on instrumentation and control systems, engineering theory and operation for nuclear power plants. Upon completion of his training, he served on-board the USS Virginia (CGN 38) qualifying as a Senior Nuclear Reactor Operator and Maintenance Technician for twin 150MW nuclear plants. Following the Virginia, Mr. Henley reported to the Nuclear Power Training Unit located within the Idaho National Engineering Laboratory outside Idaho Falls, Idaho. Assigned to the AIW Nuclear Power Training Unit, he assumed the role of Maintenance Manager for all instrumentation and controls systems of the plant, supervising 40 personnel on four rotating shifts. During this period, he also coordinated research and testing for advanced power plant cores with the Westinghouse Nuclear Engineering and Research Group. He then reported to the USS Nimitz (CVN 68) and became the Maintenance Coordinator for the Reactor Department coordinating the instrumentation, electrical, and mechanical maintenance programs for twin 550MW nuclear power plants. Upon completion of this assignment, he was one of 95 personnel selected by the Bureau of Navy Personnel from a field of over 2,100 applicants to be commissioned as an officer in the U.S. Navy and promoted to the rank of Ensign. Upon Commissioning, Mr. Henley reported to the USS Theodore Roosevelt (CVN 71) and became the Engineering Technical Manager for all electrical power generation (4,160vac) and distribution systems and the nuclear core instrumentation monitoring and control systems. Following his tour of duty on the Roosevelt, he reported to the USS Puget Sound (AD 38) as the Nuclear Repair Officer coordinating the at sea overhaul and repair efforts for surface nuclear power plants. He was then selected to head the Professional Nuclear Engineer Officer certification program for the Commander of the Atlantic Surface Fleet in Norfolk, VA. Upon retiring from the U.S. Navy after achieving the rank of Lieutenant, Mr. Henley assumed a position with the R.T. Vanderbilt company managing all aspects of the chemical and minerals processing facilities located in Murray, KY. After six years he was then promoted to the position of Project Engineering Manager coordinating all engineering projects up to a value of $5 million dollars and served in that capacity for seven years. Following his roles with the R.T. Vanderbilt company, he became the Plant Mechanical Integrity Engineer for the Ashland Specialty Chemical plant located in Calvert City, KY. In this role, he developed all regulatory mandated inspection, maintenance and repair programs for all systems containing highly hazardous chemicals constituting over 3,400 pressure vessels, heat exchangers and atmospheric storage tanks. During this period he also achieved certification by the American Petroleum Institute (API) as a pressure vessel, atmospheric storage tank, and piping inspector. These three certifications are currently held concurrently by approximately 1,200 people world wide. After retiring from Ashland in 2015, Mr. Henley assumed a position with PCI Skanska as their Mechanical Integrity Engineering Specialist in which position he managed numerous capital engineering projects and provided consultation to many plants in the areas of regulatory compliance and engineering assessments of various systems for chemical plants and underground pipeline transportation systems. He is also currently enrolled as senior level student in the Murray State University Engineering Physics program pursuing a degree in Mechanical Engineering with an emphasis on Ultrasonic Testing research and development. |

Brevin TilmonResearch Assistantbtilmon@murraystate.edu Brevin is currently a junior in Engineering Physics with an emphasis in electrical engineering. He is working on a project of nonlinear ultrasonics based on noncollinear waves mixing and flaw reconstrution. He is also actively involved in IEEE with Andrew working on coding the robot. He worked during 2017 summer as internship at Berry Plastics in Evansville, Indiana. He plans on attending grad school in an electrical engineering related field. |

Steven TreadawayResearch Assistantswest15@murraystate.edu Steven is currently a junior in Engineering Physics in the mechanical engineering track. He is currently working on implementing a research method for the study of nonlinear ultrasonic techniques to detect fatigue damage precursors on jet engine materials. Upon graduating he plans on moving to the mountains of Colorado in pursuant of a masters in engineering or other career opportunities. |

Cavir Jose GongoraResearch AssistantCavir is an international student from Belize who is currently a junior in Engineering Physics with a concentration in mechanical engineering. He is currently working on research study project of nonlinear ultrasonic techniques to detect fatigue damage precursors on jet engine materials. After graduating he aspires to further his studies and go for his masters in Aerospace Engineering. |

Jacob MyersResearch AssistantJacob is a junior in the Engineering Physics Program on the mechanical track. His current research is in flaw dimensioning with steel and aluminum specimens that have been fatigued through three-point bending tests. Using nonlinear ultrasonic techniques and wavelet cross-correlation algorithms, he is able to measure the plastic zone at the site of fatigue, specifically at the tip of the crack. Upon graduation, he intends to continue his education and to receive his masters degree in mechanical engineering, or to pursue a career within the industry.. |

Elena HammannResearch Assistantehammann@murraystate.edu Elena is currently a junior double majoring in Engineering Physics and Spanish. She is researching the flaw dimensioning of steel and aluminum specimens through nonlinear ultrasonic techniques and wavelet cross-correlation algorithms. After graduating, she aspires to obtain master degrees in engineering and business. |

Chance GlassResearch AssistantChance is in his junior year of the mechanical track for an engineering physics degree. He has fabricated better methods for more accurate and repeatable scans of specimens in our submersion tank as well as helping stitch images together for easier measurements. Once graduated, Chance plans to attend an electrical grad program or other research paths. . |

Ojoniko Nathan AbahResearch Assistantoabah@murraystate.edu Ojoniko Nathan Abah is a research student at the Jones College of Science, Engineering and Technology of Murray State University, Murray, Kentucky where he assists Mr. Jim Barnett at the Laboratory Support. He hails from Nigeria and majors in Computer Science. He is currently in his sophomore year and has a bit of experience with programming languages such as java, c++, and c as well as in the data management language, sql. |

. |

Alumni |

|

Dylan StewartPreviously Research Assistantdstewart19@murraystate.edu Dylan is interested in digital signal processing, automation engineering, and ultrasonics of metallic microstructures. He graduated in May 2017, and is currently pursuing his PhD degree at University of Florida in Electrical Engineering specializing in Digital Signal Processing. He is currently a Research Assistant in the Machine Learning and Sensing Laboratory. Based on his undergraduate GPA, GRE score and undergraduate research and publishing, he received PhD scholarships from University of Florida, Vanderbilt University, and Auburn University. He has experience working in the steel industry, improving automation and quality. When he was a student at MSU, he was working on improving nonlinear ultrasonics approaches for fatigue assessment in metals. |

Andrew YeePreviously Research Assistantayee@murraystate.edu Yee is interested in robotics and medical ultrasound. He was a member of the MSU robotics team winning second place in 2016 IEEE competition - Norfolk, VA - among 46 competing university teams. He was working on developing a nonlinear ultrasonic techniques for fatigue assessment of turbine blades of jet engines. Upon his graduation in Dec. 2017 Electrical Engineering), he started working in a cybersecurity engineering position. |