Identification of Material Damage Precursors using novel Nondestructive and/or Structural Health Monitoring Hardware

All materials degrade in time under cyclic loading, a phenomenon called material fatigue. It is desired to know when to replace a part of an engineering system before it fails, especially if this part is critical and its failure leads to catastrophic results. At Murray State we performed nonlinear ultrasonic research to detect fatigue damage precursors and predict the remaining useful life (RUL) of fatigued materials. Our research over the last years took us along several directions: harmonic generation, wave mixing, and nonlinear phased arrays.

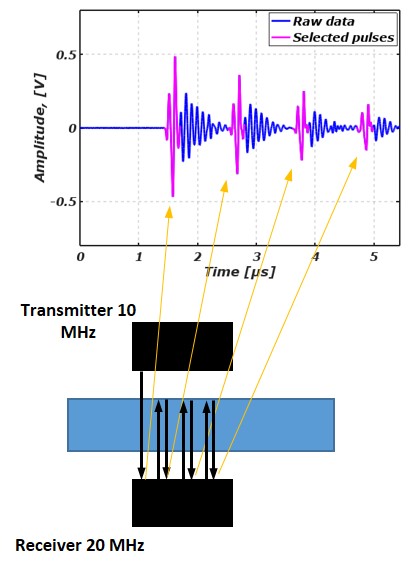

PurposeDevelop a nondestructive evaluation product (hardware) to be able to detect fatigue damage precursors in metallic aircraft or rotorcraft components and develop an accurate remaining useful life methodology. The overall objective is to develop quantitative methods and tools to improve life prediction of materials by identifying damage precursors at an earlier stage. SynopsisInvestigate the sensitivity of nonlinear ultrasonics techniques to the progression of microstructural damage precursors along the fatigue life of hot section components of jet engines. Our team designed a Wavelet Cross-Correlation algorithm to extract harmonics from wide band pulses. The nonlinearity parameter, β, is calculated based on the harmonics ratio.

Selected PublicationsYee, A., Stewart, D.R., Bunget, G., Kramer, P., Farinholt, K., Friedersdorf, F., Pepi, M., Ghoshal, A. - "Nonlinear ultrasonics measurements based on cross-correlation filtering techniques", AIP Conference Proceedings , Vol. 1806, 2017 Bunget, G.,Goff, A., Brown, N.K., Demo, J., Friedersdorf, F., Ghoshal, A., Pepi, M., Datta, S., Chattopadhyay, A. - "Identification of Material Damage Precursors using Nonlinear Ultrasonics" 51st AIAA/SAE/ASEE Joint Propulsion Conference, AIAA Propulsion and Energy Forum, Orlando, FL , 2015 |

Rotating components of aircraft engines store tremendous amounts of inertial energy. Fatigue fractured components pose a serious safety threat. Even released fragments the size of rice kernel are capable of penetrating the aircraft fuselage due to their high velocity.

×

|