Impact-Acoustic Technique for Sorting Truck Tire Casings

|

Project funded by Michelin North America, Inc. PurposeRecycling and retreading is the key for reducing costs and energy used for manufacturing of tire casings, thus the cost per mile of operations. This is an environmentally friendly technology since it conserves approximately 15 gallons of crude oil for each retread of a truck tire. However, effective retreads require tire casings with good structural integrity, i.e. without internal cracks and delaminations. The main objectives of this project were:

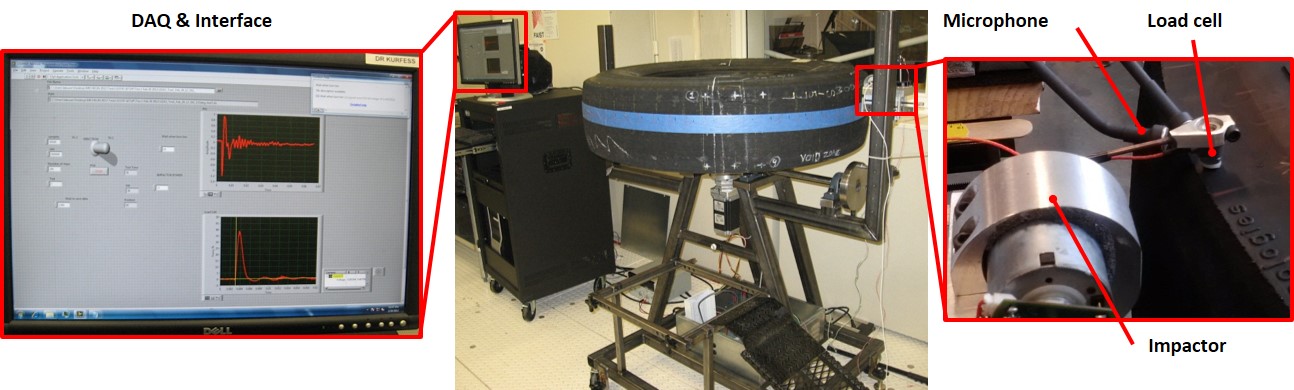

SynopsisExplore the potential of using an inexpensive nondestructive technique such as impact-acoustic to assess the presence and size of internal voids and separations in used tire casings before their retreading operation. Tested tires are tapped on each side by a small impactor containing a load cell that measures the impact force. A miniature microphone senses the acoustic waves generated under impact. A computer controls the impactor and the motor rotating the tire while in the same time records the signals from the load cell and the microphone.

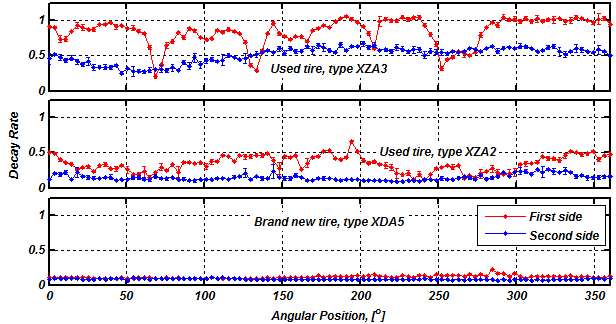

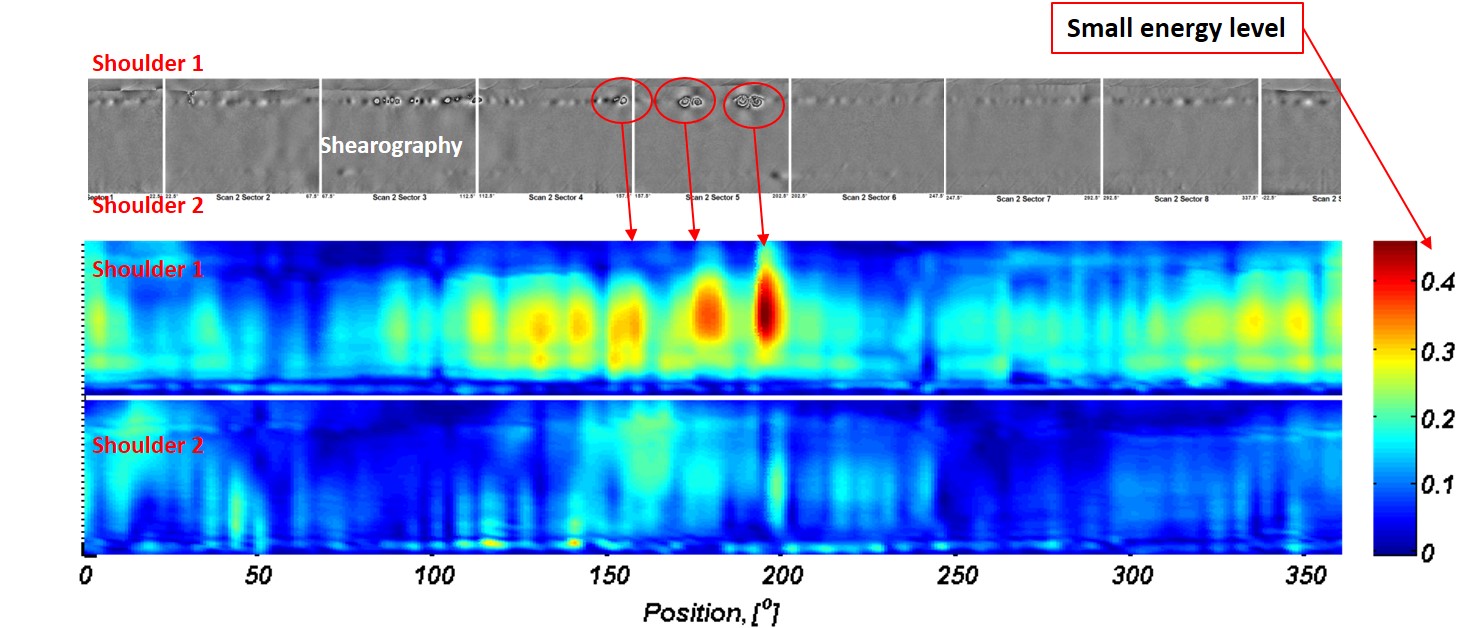

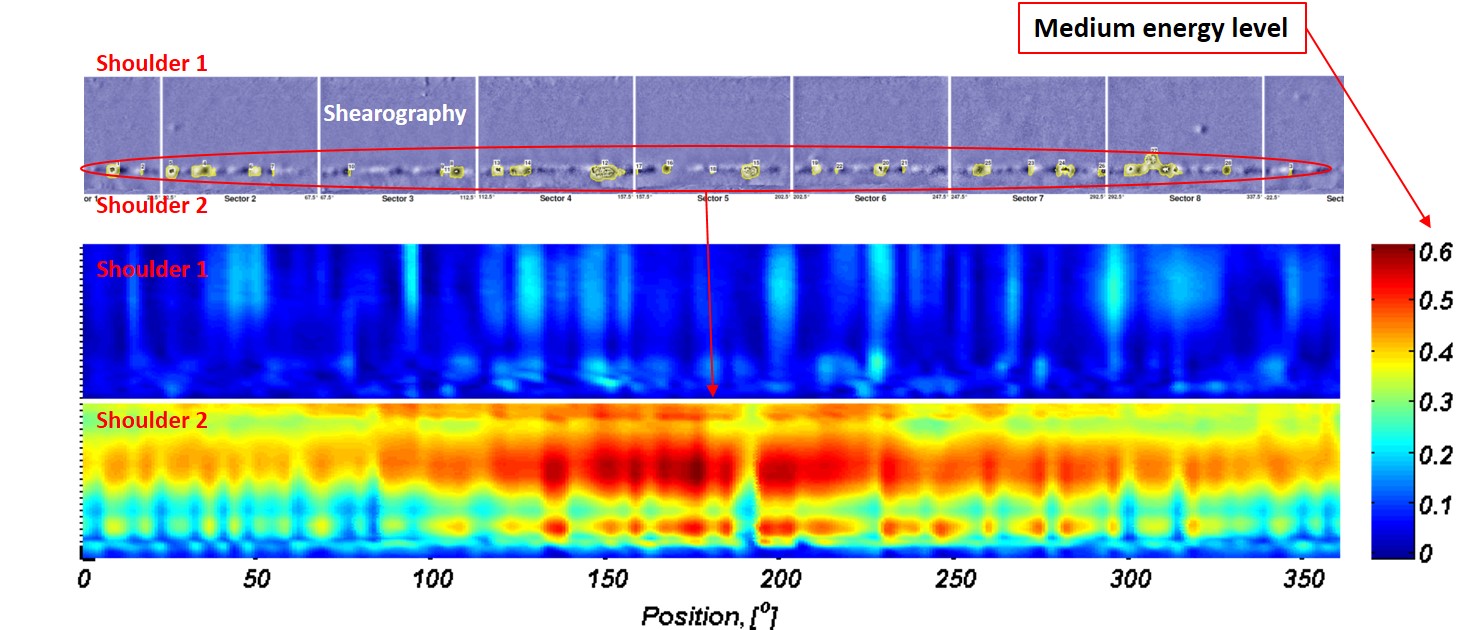

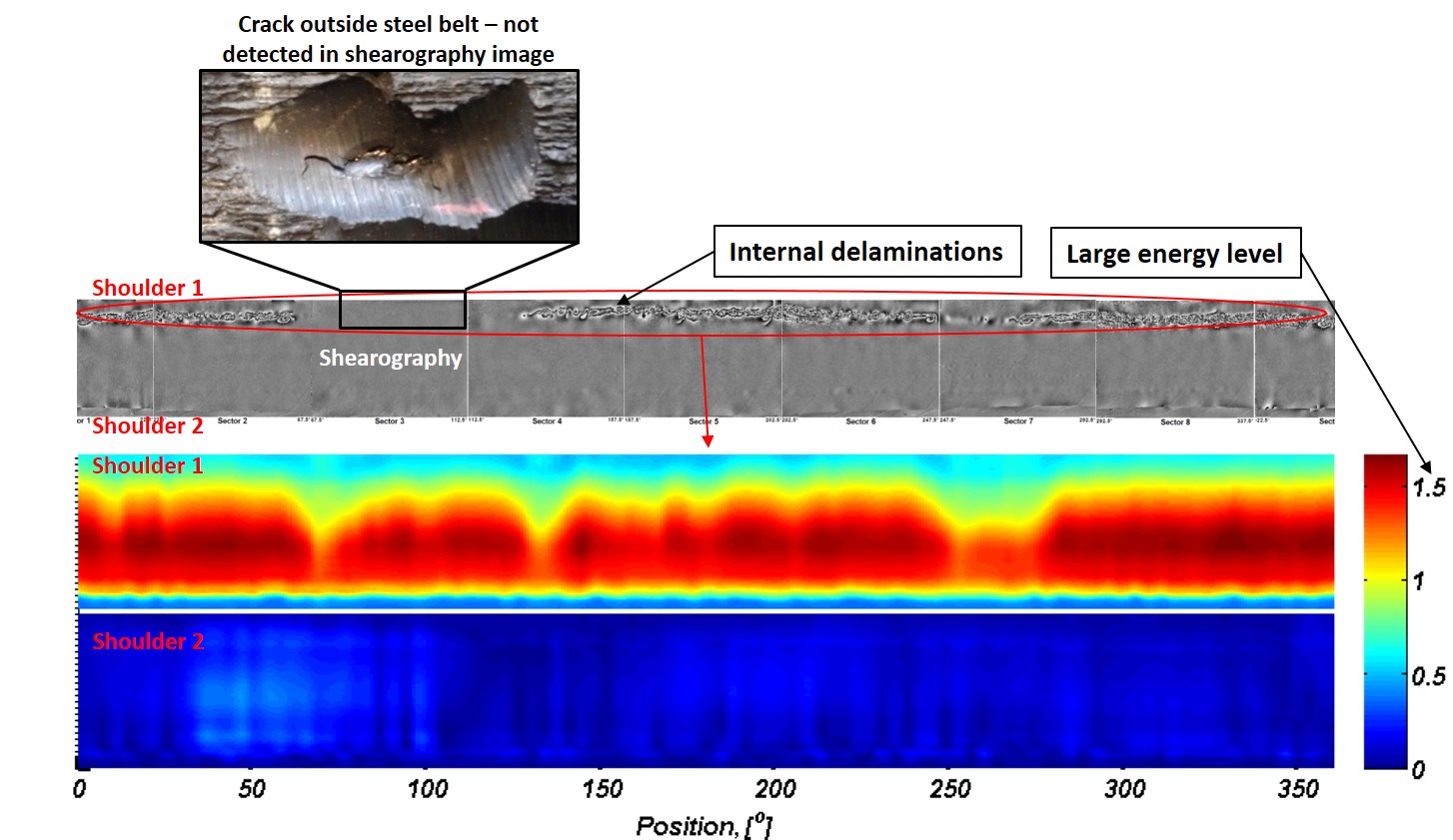

The experimental measurements showed that both the peak amplitude and the decay rate of the impact-emitted acoustic waves have a strong correlation with the size of internal delaminations estimated from shearography diagrams. The decay rate seems to be a robust indicator of defects across multiple tire structures exhibiting various levels of damage.

Selected PublicationsBunget, G., Shen, Q., Gramling, F., Judd, D., and Kurfess, T. - "Impact-Acoustic Evaluation Method for Rubber-Steel Composites: Part I. Relevant Diagnostic Concepts", Applied Acoustics Journal, Vol. 90, p74 - 80, 2015 Bunget, G., Kurfess, T., Shen, Q., Gramling, F., Judd, D. - "Method and Apparatus for Nondestructive Detection of Tire Anomalies" Patent No. WO20150 69218 A1, 2015 |

|